A crucial hub for talent developmentTechnical Training Center

A crucial hub for talent development that supports the Company

Technical Training Center was established within the Fukushima Revitalization Branch Office in 2016, so that we can continue to provide safe and high quality services to our customers. The Center conducts a wide range of technical skill courses and other training, and is a crucial hub for developing human talent that can identify the elements essential to ensuring that ATOX can continue to improve safety and quality levels. At present, there is also a branch office within the Engineering Research & Development Center at Kashiwa in Chiba prefecture.

At the Center, in addition to training in the basics of the job, we also conduct a wide range of training courses in order secure a pool of regular inspection staff associated with the restarting of nuclear power plants, and with the aim of becoming a technology team that can provide ever safer and higher quality services in anticipation of decommissioning, so that we can gain the satisfaction of our customers.

Significance and purpose of the Center as a hub for human talent development

At the Center, in addition to honing the technical skills and abilities of the staff who work at ATOX and the employees of collaborating companies, so that they will be able to carry out their duties more reliably, we are also striving to foster the kind of human talent who can acquire new skills in order to be able to take on ever more advanced tasks.

Center facilities

At the Fukushima Technical Skills Training Center, in addition to providing basic training and skill improvement training, mainly for the Fukushima Revitalization Branch Office, we are also working on training people to acquire the skills of remote operation.

The Kashiwa Technical Skills Training Center provides skill training necessary for regular inspection at nuclear power plants as well as skills training for the employees of business sites and sales offices throughout the company necessary for the acquisition of various technical qualifications.

Main types of training

Basic trainig

Hazard awareness training

For staff who are working for the first time at the Fukushima Revitalization Branch Office, we teach them about the potential dangers of the workplace, and safe and secure work practices based on the basic work procedures.

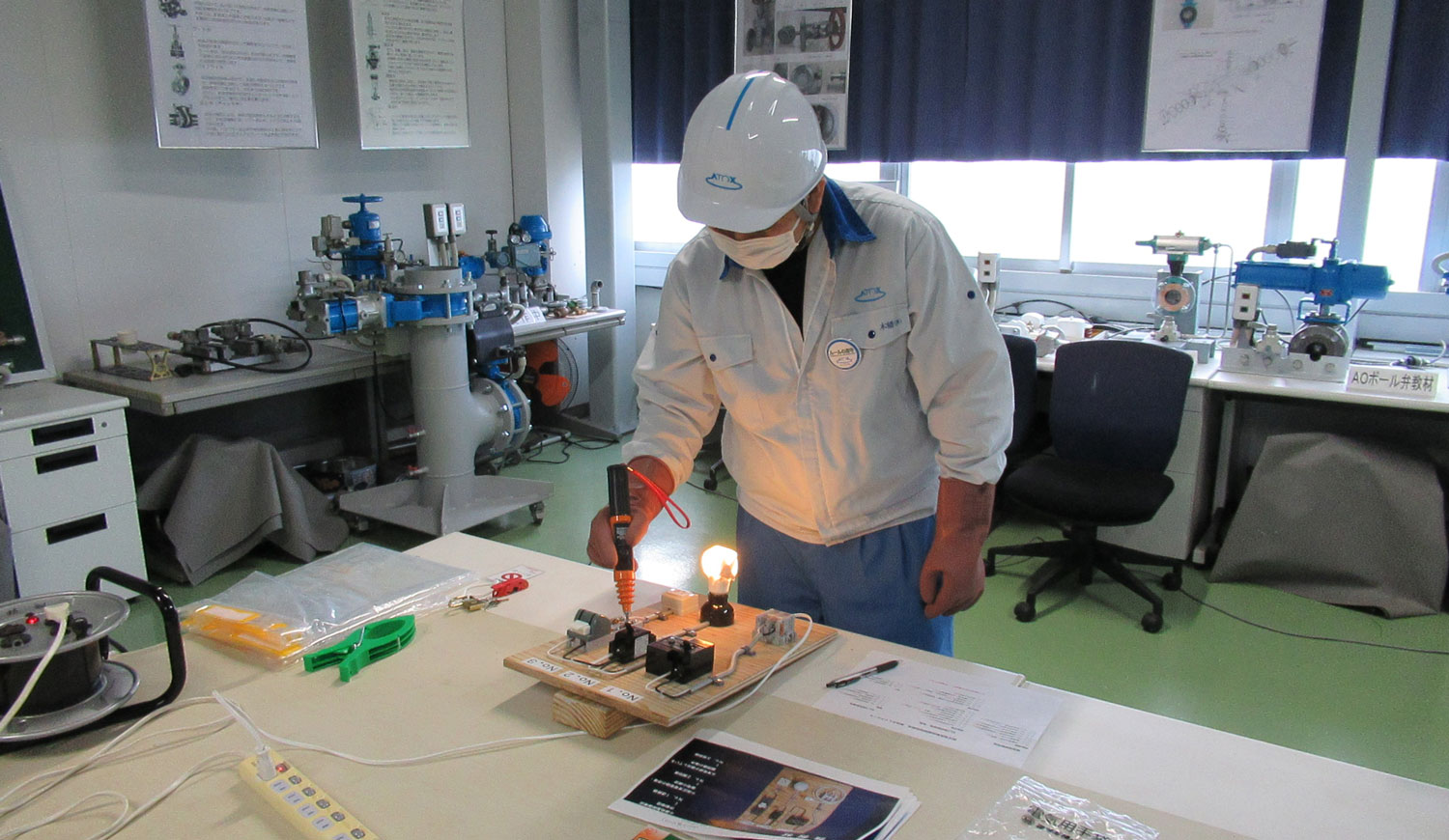

Training on electricity

We provide training for the acquisition of basic knowledge and skills, such as the basics of the electricity that trainees handle every day, the operation of switches, and the assembly of electric circuits, etc.

Remote operation skill training

Manipulator operation

We provide training for staff who will play an important role in the revitalization of Fukushima by acquiring the technical skills to operate manipulators that will be used in the decommissioning of Fukushima Daiichi Nuclear Power Plant.

Robot operation

We provide training in robot remote control operations so that work can be carried out in the high radiation dose environments at Fukushima Daiichi Nuclear Power Plant.

Qualification acquisition support

Non-destructive Testing Personnel

We provide training for staff who are attempting to pass the practical testing for penetrant testing technicians who check for cracks in welded parts, and ultrasonic testing technicians who measure metal thickness.

Qualified Electrician 2nd Class

The Center provides hands-on training that simulates the practical tests for the Qualified Electrician 2nd Class examination.

Building Cleaning Technician

For staff aiming to acquire specialized skills in building cleaning, the Center provides skill training so that they can pass the practical tests in each category (1st Class, 2nd Class, 3rd Class).

Skill enhancement training

Temporary pump assembly and disassembly

Training in the principles and structures of the diaphragm pumps and submersible pumps that we use helps our engineers to be ready to troubleshoot any problems that may arise on site.

Cutting technology

The Center provides training in cutting for different sites, such as plasma cutting and gas cutting (using gasoline) in the disposal of metal waste.

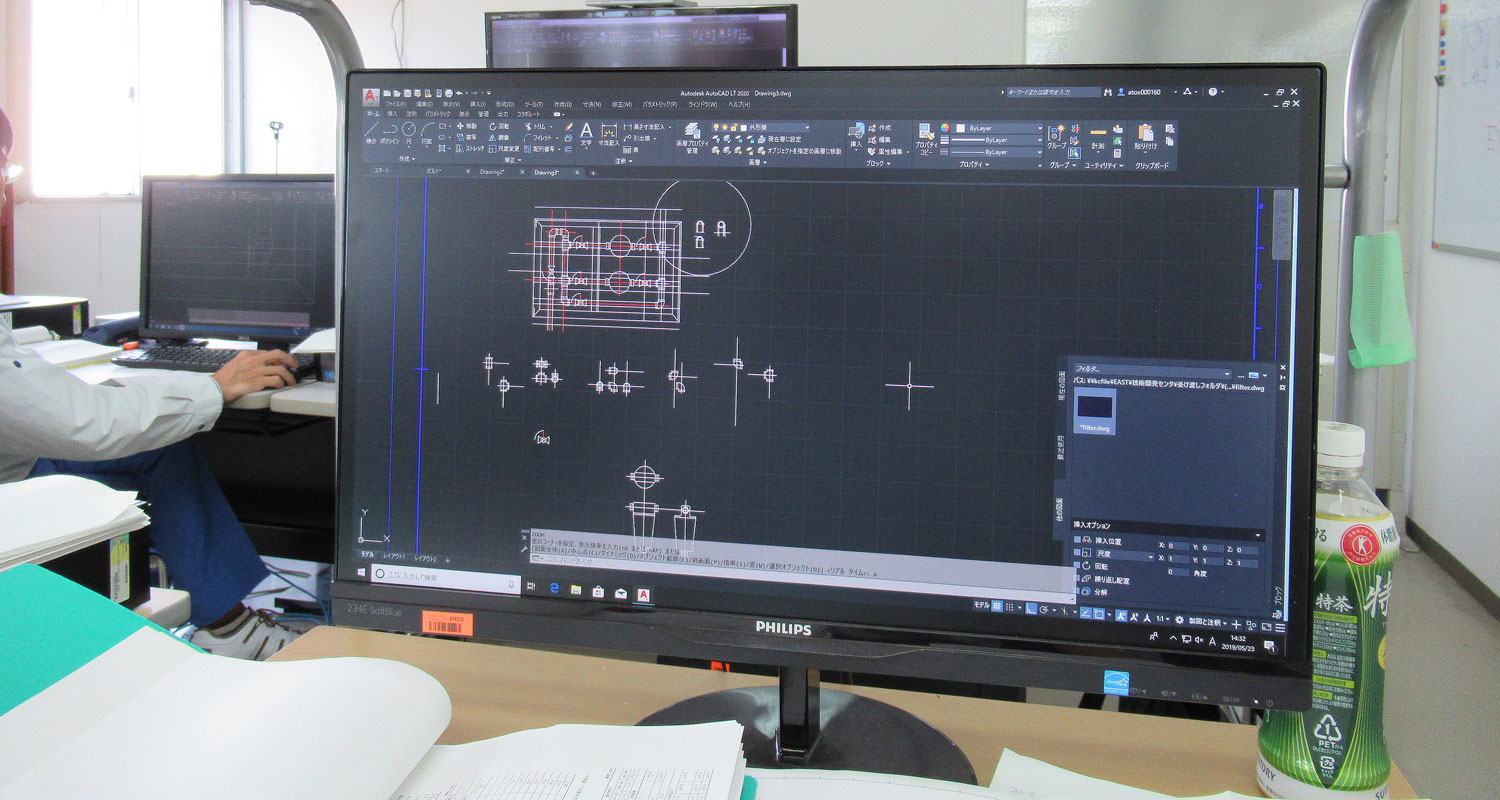

AutoCAD

Training is provided in the acquisition of the basic skills of CAD system operation.

Radiation meter operation

For employees who have been with the Company for a year, and who have around six months experience in readiation management, we provide training in the and knowledge of radiation meters.

Equipment operator training

In order to practice realistic on-site operations, the Center provides training that simulates conditions in the workplace, from starting up equipment beginning with operation procedure confirmation and pointing and calling checks, to starting and stopping pumps, responding in the event of an emergency, and reporting and contact procedures.

Other training

In addition to repetitive training in forklift operation and slinging and hanging equipment, etc., the Center also provides work training for improved safety, such as pipe cleaning, the handling of power tools and operational training for suction vehicles and high pressure JET washer operators.

Special training

Full harness (fall accident prevention equipment)

Special training is provided for workers who need to used full harnesses (fall accident prevention equipment), in order to ensure that they have the knowledge required to use and attach the harnesses.

Low voltage electricity operations

In order to prevent electric shock accidents caused by low voltage electricity (600 VAC, 750 VAC or lower), we provide special training in the basic knowledge related to low voltage and how to work in the vicinity of live lines.

Replacement and trial operation of free grinding wheels

In order to prevent accidents caused by broken grinding wheels, the Center provides special training in the basic knowledge how to handle electric grinders, table top grinders, and high-speed cutting machines, and how to replace their grinding wheels.